An Integrated Anode Developed for High-Specific-Energy, Long-Cycling Lithium Metal Batteries

The research group led by Prof. WAN Lijun and Prof. GUO Yuguo from the Institute of Chemistry of the Chinese Academy of Sciences (ICCAS) developed an ultra-light, functionalized integrated anode that significantly improves the cell-level specific energy and long-term cyclability of lithium metal batteries (LMBs).

The research was published in Science Advances on Mar. 29, 2024.

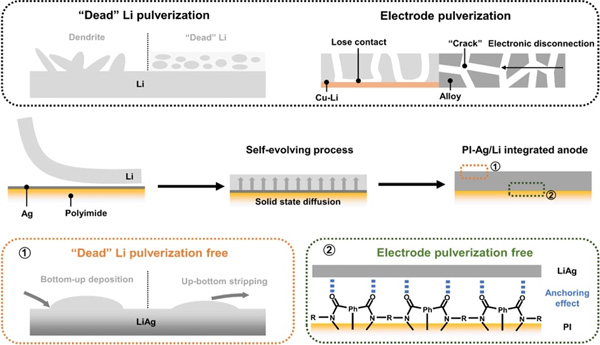

Under the trend of pursuing higher specific energy levels, the amount of lithium used in batteries requires to be minimized. With the thinning of lithium foils, the high-density copper (Cu) foils currently used for negative electrodes has become a major factor limiting their high specific capacity. Moreover, for lithium-limited batteries, cycling performance is notably compromised by the accumulation of “dead” lithium and the pulverization resulting from electrode cracking.

To address these issues, researchers utilized ultra-light polyimide (PI) as a substrate and chemically immobilized silver (Ag) monolayers onto PI via ion-ligand exchange reactions. An integrated anode was realized by electrodeposition or lamination of ultra-thin Li foil on top of PI-Ag (referred to as PI-Ag/Li). The mass of inactive material in the integrated anode is reduced by 50% compared to Cu foil. As a result, the cell-level specific energy of a full cell was increased by 10% compared to the cutting-edge anode-free cell using a Cu foil anode.

The Ag phase diffused in Li solid solution and self-evolved into a fully lithiophilic, homogeneous LiAg alloy, which facilitates uniform lithium deposition and mitigates “dead” Li pulverization. Additionally, the strong interactions between lithium-silver alloy and polyimide (LiAg┅O=C) enable a good electrode integrity and electrical continuity upon cycling, thus effectively suppressing electrode pulverization.

Researchers assembled half cells and full cells, demonstrating that the integrated anode (PI-Ag/Li) exhibits superior cycling stability compared to the conventional Cu-foil anode. Impressively, under a highly practical condition of high-areal-loading cathode (20 mg cm-2) and ultralow negative/positive capacity ratio (1.0), PI-Ag/Li||LiNi0.8Mn0.1Co0.1O2 full cells can maintain a remarkably stable cycling with capacity retention of 90% over 170 cycles. Researchers also assembled pouch cells with PI-Ag/Li anodes and LiNi0.8Mn0.1Co0.1O2 cathodes, which shows excellent cycling performance under realistic testing conditions.

Moreover, the high-energy LMBs equipped with the integrated anode demonstrate a superior high-safety characteristic that can effectively block heat propagation under extreme conditions such as short circuits and thermal runaway.

This study provides a new way to boost the specific energy of LMBs, and provides scientific guidance for circumventing pulverization problems in the practical implementation of high-capacity anodes, which is expected to benefit other alloy anode or alkali metal batteries.

Schematic illustration of the construction and functionality of PI-Ag/Li anode (Image by ZHANG Chaohui)

Contact:

Prof. Guo Yuguo

Institute of Chemistry, Chinese Academy of Sciences

Email: ygguo@iccas.ac.cn

| Download the attachment: |