Scientists Advance Wearable Large-Scale Perovskite Solar-Power Source

Wearable electronic devices have triggered extensive research interest for next generation artificial intelligence equipment. Electric power source is the core part of wearable electronic devices. Generally, most current wearable devices need batteries, even when they are used in places where solar energy is plentiful. Compared with traditional power sources, perovskite solar cells show lightweight, flexible advantages, as well as excellent photovoltaic efficiency. Design of wearable large-scale solar power source based on perovskite films is important.

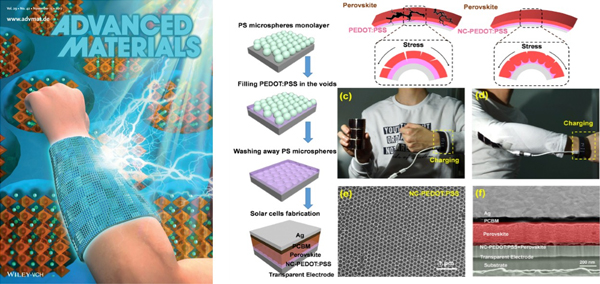

Recently, Professor SONG Yanlin and cowokers from Institute of Chemistry, Chinese Academy of Sciences develop a nano-cellular scaffold for interfacial layer to architect optical resonant cavity and mechanical buffer layer in flexible perovskite solar cells. The nano-cellular scaffold innovatively solve the critical challenges of reproducibility and stability of large-area flexible perovskite solar cells. It is the first time to practically fabricate a wearable solar power, which can supply power for multifunction electronic devices with a variety of body movements. The work has been published in Adv. Mater. (Adv. Mater.2017,29,1703236)

Fabrication and morphological characterizations. (Image by Prof. SONG Yanlin)

The nano-cellular scaffold is fabricated via a facile solution lithography. The common polymer transporting layer is constructed into cellular shape via efficient printing process with nanoparticles assembly. The nano-cellular scaffold significantly improves the crystalline quality of perovskite films and light harvesting of solar cells devices. Moreover, this nano-cellular scaffold effectively releases the mechanical stresses of flexible devices to protect the perovskite crystalline layer during bending. The authors successfully fabricated hysteresis-free, flexible and large-scale perovskite solar cells with recorded efficiencies of 12.3 % for 1 cm2 single chip and 8.4 % for 24 cm2 solar module, respectively. The printable nano-scaffold contributes the mechanical design for new laminated devices, which will open the prospect for advances of future flexible and wearable electronics.

Contact:

Prof. SONG yanlin

Institute of Chemistry, Chinese Academy of Sciences

Email: ylsong@iccas.ac.cn