By Yu Wang, Chong-an Di, Yunqi Liu,* Hisashi Kajiura,* Shanghui Ye, Lingchao Cao, Dacheng Wei, Hongliang Zhang, Yongming Li, and Kazuhiro Noda

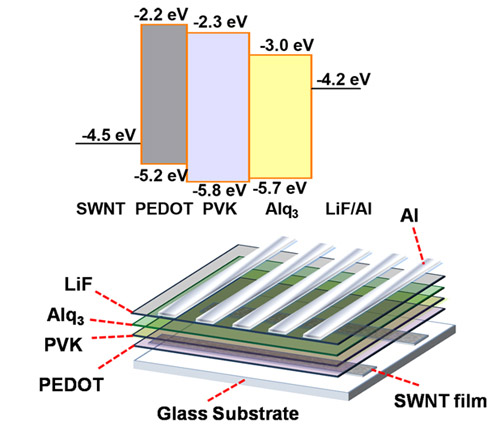

We report a multistep purification method (Fig. 1) for improving the conductivity of flexible transparent conducting thin single-walled carbon nanotube (SWNT) films. It is demonstrated that the residual surfactants and filtration membrane have a great impact on the sheet resistances of SWNT films produced by the filtration method. Our designed steam generator can very quickly and completely remove the filtration membrane, in contrast to the general immersion method. At the same time, SWNTs are not destroyed by our “soft method”, which will allow for expanded applications in electroluminescent or photovoltaic devices. Moreover, combining the percolation theory and the chemical modification method, we propose a novel SWNT film with sandwich structure. The SWNT films and their chemical modification were characterized by a set of characterization methods including Fourier transfer infrared, Raman, X-ray photoelectron spectroscopy and scanning electron microscopy. Experimental results show that the sheet resistances of the four-layer SWNT films can be reduced to 56 W/sq when the transparency of the film is 77.6%. Electroluminescent devices (Fig. 2) fabricated by using the ultimately optimized films as anodes for organic light‑emitting diodes demonstrate a maximum luminance of 1992 cd/m2 and a current efficiency of 1.19 cd/A. The transparent and conducting SWNT films demonstrate a great potential for applications in optoelectronic devices.

Advanced Materials , 2008, 20(23), 4442-4445

Figure 1 A schematic illustration of the multistep purification process for the SWNT films.

Figure 2 The Energy diagram of the fabricated device with structure of SWNT/PEDOT:PSS/PVK/Alq3/LiF/Al and the device structure of fabricated multilayer OLED

,