Lithium ion batteries using carbonaceous anode materials have the risk of safety problems when operating under high current densities as power sources. The carbon-free anode material of Li4Ti5O12 (LTO) is a star material to solve the safety issue. However, low kinetics associated with its electrical conductivity limit its high-rate capability in practical applications, and the reported carbon nanocoating strategy again incurs a safety problem.

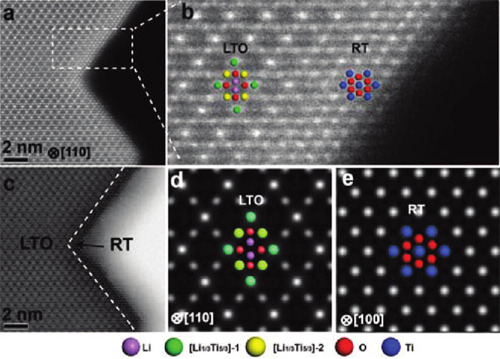

Recently, researchers of Prof. GUO Yuguo and Prof. WAN Lijun’s groups from the Institute of Chemistry, the Chinese Academy of Sciences(ICCAS), developed a new carbon-free nanocoating material of rutile-TiO2 for a high-rate Li4Ti5O12 anode of a lithium-ion battery. Co-operating with researchers of IoP, and Tohoku University, they have demonstrated the utility of rutile-TiO2 as a carbon-free nanocoating to improve the kinetics of LTO toward fast lithium insertion/extraction. Well-defined LTO nanosheets terminated with rutile-TiO2 at the edges were synthesized by a facile solution-based method and revealed directly at atomic resolution by an advanced spherical aberration imaging technique (Figure 1). The rutile-TiO2 terminated LTO nanosheets (LTO-600) show much improved rate capability, specific capacity and cycling performance compared with pure LTO nanosheets (LTO-RT-600) when used as anode materials for lithium ion batteries (Figure 2).

The LTO-RT-600 has a high reversible capacity of 178 mA h/g at 1 C. At the highest rate of 60 C, corresponding to a time of 60 s to fully discharge/charge the materials, the LTO-RT-600 still delivers a capacity of 110 mA h/g, which is much higher than that of LTO-600 (ca. 10 mA h/g).

The carbon-free nanocoating of rutile-TiO2 not only is proven to be highly effective but also promises high surface stability and long cycle life electrode materials compared with the commonly used carbon nanocoating in electrode materials. The strategy of tuning the surface termination of active material is simple yet very effective because of its versatility, it may also be extended to other anode and cathode materials for future high energy density and high power density Li ion batteries used in electric vehicles and large-scale energy storage.

The findings may also trigger interest in studies of the effects of off-stoichiometry on the electrochemical performance of LTO.

Under the supports of the National Natural Science Foundation of China, the Chinese Ministry of Science and Technology, and the Chinese Academy of Sciences, the results have been published in J. Am. Chem. Soc., (2012, 134, 7874−7879) as an Article. (http://pubs.acs.org/doi/abs/10.1021/ja301266w)

Figure 1. Scanning transmission electron microscopy (STEM) images of rutile-TiO2 terminated LTO nanosheets (LTO-RT-600)( Image by GUO Yuguo).

Figure 2. Electrochemical performances of the LTO-RT-600 and LTO-600 NSs( Image by GUO Yuguo).