Researchers Develop Kinetic Decoupling–Recoupling Strategy for Selective Conversion of Polyethylene to Ethylene and Propylene

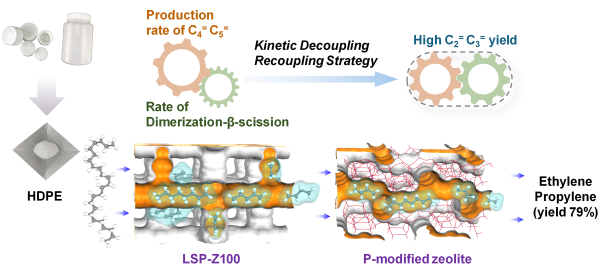

Prof. HAN Buxing and LIN Longfei ’s group at the Institute of Chemistry, Chinese Academy of Sciences, in collaboration with Beijing Normal University and Peking University, developed a kinetic decoupling–recoupling (KDRC) strategy that enables the conversion of PE to ethylene and propylene with a yield of 79%.

Plastic waste, particularly polyethylene (PE), poses severe environmental challenges due to its large-scale accumulation and resistance to degradation. Chemical recycling that converts waste polyolefins back into monomer (e.g. ethylene and propylene) is essential for establishing a circular plastic economy. However, conventional catalytic cracking methods suffer from low selectivity and high energy consumption.

To address the issue of kinetic entanglement in single-stage reaction systems, which has persistently limited the yield improvement of ethylene and propylene from PE cracking, the researchers designed a two-stage reaction system. By developing a reaction kinetic model and implementing the KDRC strategy, they successfully optimized the reaction condition in each reaction stage. In Stage I, a layered self-pillared zeolite (LSP-Z100) selectively cracks PE into intermediate compounds (primarily butenes and pentenes) at 260 °C. In Stage II, a phosphorus-modified HZSM-5 (P-HZSM-5) zeolite converts these intermediates into ethylene and propylene via dimerization-β-scission at 540 °C.

To validate the reaction pathway, synchrotron-based vacuum ultraviolet photoionization mass spectrometry (SVUV-PIMS) was employed to detect transient reaction. It provided direct experimental evidence of dimerization–β-scission pathway via capturing C8 intermediates. In situ neutron powder diffraction (NPD) was employed to reveal the precise locations of acid sites, showing that phosphorus modification suppressed the occurrence of bimolecular side reactions by reducing acid site density, thereby enhancing selectivity of ethylene and propylene.

Notably, this catalytic reaction system operates without noble metals, or external hydrogen. It also demonstrated high catalytic performance in processing real-world plastic wastes and the catalysts can be recycled. This work offers a practical and efficient route for plastic waste recycling.

Kinetic decoupling–recoupling (KDRC) strategy enables the production of ethylene and propylene from polyethylene (Image by BI Tianrui)

This study was published in Nature Chemical Engineering

Contact:

Prof. LIN Longfei, Prof. HAN Buxing

Institute of Chemistry, Chinese Academy of Sciences

Email: linlongfei@iccas.ac.cn, hanbx@iccas.ac.cn