Researchers develop a bubble-template printing method for precise patterning at molecular scale

Patterning is one of the research foundations in the fields of nanofabrication, nanomaterials assembly and bioengineering. Ultrahigh-precision patterning at the molecular scale is extremely attractive for the integration fabrication of high-sensitivity sensors and high-performance optoelectronic devices. Due to the incompatibility of traditional photolithography with organic functional molecules, many high-precision non-lithographic patterning techniques, such as dip-pen nanolithography, nanoimprint lithography, block-copolymer self-assembly, and DNA-Origami lithography have been developed. However, an efficient approach to achieve ultra-precise molecular patterns with simple operation, template-independent precision, controllable molecular assembly, and wide molecular generalization is still challenging.

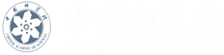

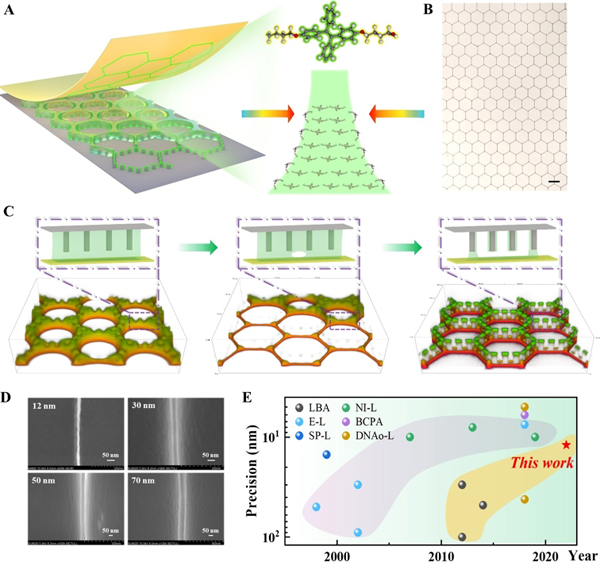

Recently, the research team led by Prof. SONG Yanlin and Prof. QIAO Yali from the Institute of Chemistry, Chinese Academy of Science (ICCAS), together with Prof. YAN Xuehai from the Institute of Process Engineering (IPE), Chinese Academy of Sciences (CAS), and other collaborators, proposed a bubble-template molecular printing concept by introducing the ultrathin liquid film of bubble walls as a soft confinement space, and achieved ultrahigh-precision assembly up to 12 nm corresponding to the critical point towards the Newton black film limit. Using the template of bubble arrays, various molecular assembly morphologies were realized without additional surfactants by controlling the bubble rupture location and confirmed by in-situ visualization based on the aggregation-induced emission property of the model molecules. The researchers also pointed out that the disjoining pressure describing the intermolecular interaction between two liquid-air interfaces could predict the highest precision effectively from the perspective of dynamic evaluation of thin liquid film in the foam system. Furthermore, researchers experimentally and theoretically revealed the molecular assembly mechanism in the bubble wall confinement space, and demonstrated that the molecular symmetry is the key point to stabilizing the evolution of foam film and pursuing ultimate precision molecular patterns. The symmetric molecules exhibit better reconfiguration capacity and smaller pre-aggregates than the asymmetric ones, which are helpful to stabilize the drainage of foam films and construct high-precision patterns.

This work affords a guiding clue to construct molecular-level patterns precisely. Combining with the molecular engineering, this method would provide promising opportunities for the fabrication of nano- and molecular-scale devices with unique nanoconfinement and performance enhancement. The study entitled “Bubble wall confinement-driven molecular assembly towards sub-12 nm and beyond precision patterning” was published inScience Advances2023, 9, eadf3567.

Bubble-template molecular printing (BTMP) method. (Image by QU Zhiyuan)

The ultrathin liquid film evolution and molecular assembly mechanism. (Image by QU Zhiyuan)

Contact:

Prof. SONG Yanlin

Institute of Chemistry, Chinese Academy of Sciences

Email: ylsong@iccas.ac.cn